supply chain resilience

Mastering Supply Chain Resilience: Navigating Global Risks

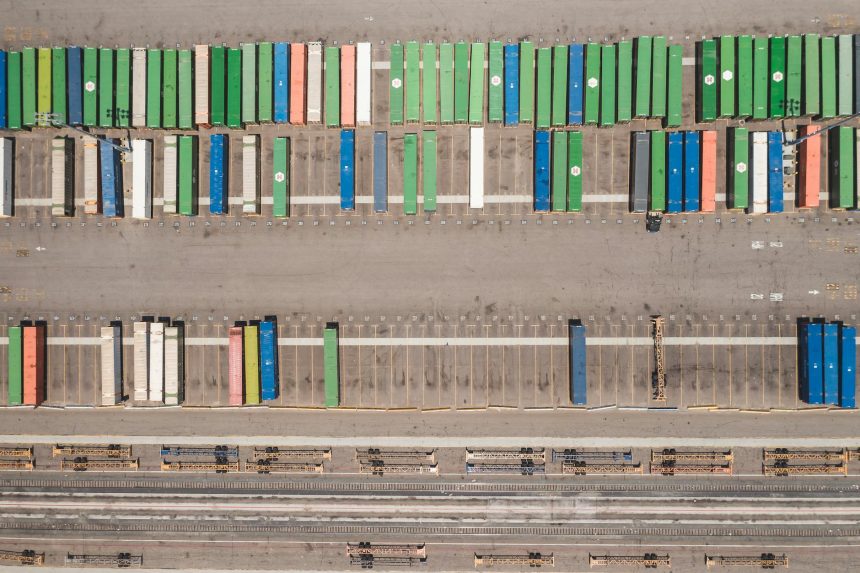

The world is more interconnected than ever, yet the pathways of commerce are increasingly fraught with peril. Geopolitical shifts, natural disasters, and unexpected global events have exposed a stark reality: traditional supply chain management, focused solely on cost and speed, is no longer sufficient. Businesses must now prioritize building robust, adaptable networks capable of withstanding disruption. This is the essence of mastering supply chain resilience.

Why Traditional Supply Chain Management Falls Short

For decades, the mantra of supply chain operations was “lean and mean.” The goal was to minimize inventory, streamline processes, and reduce lead times, all in the pursuit of lower operational costs. While this approach yielded significant efficiencies, it inadvertently created brittle systems. A single point of failure, a distant supplier disruption, or a sudden trade dispute could send shockwaves through the entire network, halting production and impacting customer delivery.

The Hidden Costs of Inefficiency

While cost savings were the primary driver, the focus on efficiency often overlooked the potential for massive financial losses during disruptions. These costs can include:

- Lost revenue due to stockouts.

- Increased expedited shipping fees.

- Damage to brand reputation and customer trust.

- Production downtime and idle labor costs.

- Penalties for late deliveries.

The Imperative of Supply Chain Resilience

Supply chain resilience isn’t just a buzzword; it’s a strategic necessity for survival and growth in today’s volatile environment. It involves designing and managing supply chains to anticipate, withstand, and recover from disruptions quickly and efficiently. This proactive approach shifts the focus from merely reacting to crises to building inherent strength.

Key Pillars of a Resilient Supply Chain

Building a resilient supply chain requires a multi-faceted strategy. Here are the core components:

- Diversification: Reducing reliance on single suppliers or geographic regions. This involves identifying alternative sources and manufacturing locations.

- Visibility: Gaining end-to-end insight into your supply chain, from raw materials to the final customer. This allows for early detection of potential issues.

- Agility: The ability to adapt quickly to changing circumstances. This includes flexible manufacturing capabilities and responsive logistics.

- Collaboration: Fostering strong relationships with suppliers, partners, and even competitors to share information and coordinate responses during crises.

- Risk Management: Proactively identifying, assessing, and mitigating potential risks across the entire supply chain ecosystem.

Strategies for Building Supply Chain Robustness

Moving from a fragile, efficiency-driven model to a resilient one involves concrete actions. It’s about embedding adaptability at every level.

Leveraging Technology for Enhanced Visibility

Modern technology offers powerful tools to enhance supply chain visibility. Solutions like IoT sensors, blockchain, and advanced analytics platforms can provide real-time data on inventory levels, shipment status, and potential bottlenecks. This data empowers informed decision-making and faster response times.

Developing a Robust Risk Assessment Framework

A comprehensive risk assessment is the foundation of resilience. This involves:

- Identifying potential threats: geopolitical instability, natural disasters, cyberattacks, pandemics, economic downturns.

- Assessing the likelihood and impact of each threat.

- Developing mitigation strategies and contingency plans for high-priority risks.

- Regularly reviewing and updating the risk assessment as the global landscape evolves.

Strengthening Supplier Relationships

Your suppliers are critical partners in building resilience. Cultivating strong, collaborative relationships can lead to greater transparency and a willingness to work together during challenging times. Consider dual-sourcing strategies and exploring partnerships with suppliers in different geographic locations.

The Role of Data Analytics in Proactive Management

Data analytics is no longer a luxury but a necessity for proactive supply chain management. By analyzing historical data and real-time information, businesses can identify patterns, predict potential disruptions, and optimize inventory levels. This predictive capability allows for preemptive action rather than reactive firefighting. For more on understanding global trade dynamics, explore resources from the World Trade Organization.

Conclusion: Embracing a Resilient Future

The era of prioritizing pure efficiency in supply chain management is over. The complexities of the modern world demand a strategic shift towards resilience. By embracing diversification, enhancing visibility, fostering agility, and leveraging technology, businesses can build supply chains that not only withstand disruption but emerge stronger from it. This proactive approach is not just about managing risk; it’s about securing long-term competitive advantage and ensuring business continuity in an unpredictable global landscape. Ready to fortify your operations?

Call to Action:

Start your journey towards a more resilient supply chain today. Explore our expert guides and discover how to future-proof your business against unforeseen challenges.

© 2025 thebossmind.com

Featured image provided by Pexels — photo by RDNE Stock project