critical-power-plant-safety

Critical Power for Plant Safety: 5 Ways to Prevent Disaster

Imagine a massive industrial facility, humming with complex machinery, suddenly plunged into darkness. It’s not just a power outage; for many plants, it’s a direct threat to safety, environmental integrity, and even human lives. The critical reliance on electricity to maintain essential cooling and safety systems is paramount, making **Critical Power for Plant Safety** not just an operational concern, but a fundamental pillar of disaster prevention.

Understanding the Peril: Why Critical Power for Plant Safety Matters

In high-stakes environments, from nuclear power stations to chemical processing plants, an uninterrupted power supply isn’t a luxury—it’s a non-negotiable requirement. A sudden loss of electricity can cripple vital functions, leading to overheating, uncontrolled reactions, or the release of hazardous materials. The consequences can range from significant financial losses to widespread environmental damage and public health crises.

The Role of Cooling and Safety Systems

Cooling systems, for instance, prevent equipment from exceeding safe operating temperatures, crucial for processes that generate immense heat. Safety systems, on the other hand, encompass everything from emergency shutdown mechanisms to ventilation and fire suppression. Both are typically electricity-dependent, and their failure can cascade into a catastrophic event. Without reliable power, these safeguards become inert, leaving facilities vulnerable.

5 Essential Strategies for Robust Industrial Safety Systems

Ensuring the continuous operation of these critical systems demands a multi-layered approach to power management. Here are five vital strategies to fortify your plant’s resilience against electrical disruptions:

- Redundant Power Sources: Implement multiple, independent power feeds. This could include connections to different grid substations, on-site backup generators, and Uninterruptible Power Supply (UPS) systems to bridge gaps during switchovers.

- Advanced Monitoring & Control Systems: Utilize real-time monitoring of power consumption, voltage fluctuations, and system health. SCADA (Supervisory Control and Data Acquisition) and DCS (Distributed Control Systems) can provide early warnings and automate responses to maintain stability.

- Regular Maintenance & Testing: Proactive maintenance of all power infrastructure, from transformers to battery banks, is crucial. Routine testing of emergency power solutions under realistic load conditions ensures they will perform when needed most.

- Comprehensive Emergency Response Protocols: Develop and regularly practice detailed plans for various power failure scenarios. This includes clear communication chains, manual override procedures, and designated teams trained to respond swiftly and effectively.

- Cybersecurity for Control Systems: Protect your digital control systems from cyber threats that could disrupt power delivery or manipulate safety protocols. A robust cybersecurity framework is integral to overall energy security.

Implementing Redundant Power: A Deeper Dive

Redundancy is the cornerstone of **Critical Power for Plant Safety**. It’s about having a backup for your backup. Consider these components:

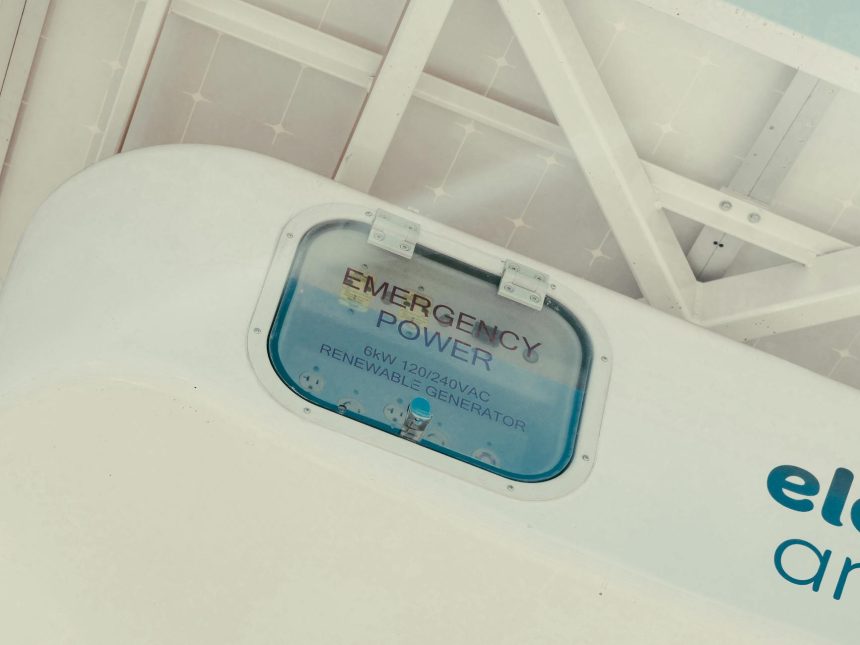

- Uninterruptible Power Supply (UPS): Essential for instantaneous power during brief outages or transitions, protecting sensitive electronics and control systems.

- Backup Generators: Diesel or natural gas generators provide longer-term power, kicking in automatically when grid power fails. They require regular fuel checks and maintenance.

- Grid Diversification: Where feasible, connect to separate utility grids or substations to minimize the risk of a single point of failure affecting your primary power.

Navigating External Threats & Operational Risks

Beyond internal failures, external factors such as extreme weather, natural disasters, or even geopolitical instability can pose significant threats to power infrastructure. The increasing interconnectedness of global energy markets and supply chains means that a disruption far away can have ripple effects on local operations. Proactive risk assessment must consider these broader vulnerabilities.

Proactive Measures for Unforeseen Disruptions

Building operational resilience requires thinking beyond the immediate plant perimeter. This includes evaluating the reliability of your energy suppliers, understanding regional grid vulnerabilities, and developing contingency plans for scenarios like fuel shortages or damaged transmission lines. Collaborating with local authorities and utility providers can also enhance preparedness.

Conclusion: Securing Your Future with Reliable Plant Power

The imperative for **Critical Power for Plant Safety** cannot be overstated. From maintaining cooling systems to ensuring emergency shutdowns, electricity is the lifeblood of modern industrial operations, directly linked to disaster prevention. By investing in redundant systems, advanced monitoring, rigorous maintenance, and comprehensive emergency planning, facilities can significantly mitigate risks and safeguard against catastrophic failures. Proactive measures and a holistic approach to energy security are not merely best practices; they are essential for protecting assets, the environment, and human lives. Ensure your facility’s resilience by evaluating your current power safety protocols today, and fortify your defenses against the unforeseen.

© 2025 thebossmind.com

Discover how robust Critical Power for Plant Safety systems are essential to prevent catastrophic failures. Learn 5 vital strategies to secure your operations and safeguard against disaster.

Featured image provided by Pexels — photo by Kindel Media