bubble shear stress

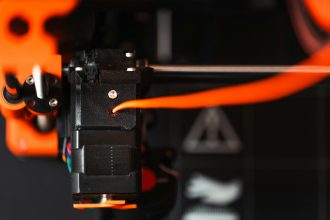

Unlocking Microfluidic Precision: The Power of Electrochemically Generated Bubbles

Microfluidics, the science of manipulating tiny volumes of fluids, is revolutionizing fields from medicine to materials science. But achieving precise control at such minuscule scales presents significant challenges. Now, researchers are harnessing a novel approach: electrochemically generated bubbles. These tiny, controlled bursts of gas are proving to be a game-changer, offering unprecedented ways to influence fluid behavior through their unique shear stress properties.

The Challenge of Microfluidic Control

Controlling fluid flow in microchannels is far from straightforward. Traditional methods often struggle with issues like low Reynolds numbers, where viscous forces dominate inertia, making precise manipulation difficult. The need for non-invasive, highly localized forces has driven innovation, leading to the exploration of various physical phenomena.

Electrochemical Bubbles: A New Frontier

At the heart of this breakthrough lies the controlled generation of gas bubbles through electrochemical reactions. By applying a voltage across electrodes immersed in an electrolyte solution, water molecules can be split, producing hydrogen and oxygen gas. The key innovation is the ability to precisely control the size, frequency, and location of these bubbles.

How Bubble Shear Stress Works

When an electrochemically generated bubble forms and grows within a microchannel, it displaces the surrounding fluid. This displacement creates a localized disturbance, a phenomenon known as shear stress. The bubble’s surface acts like a miniature piston, pushing fluid away and generating a flow field around it.

* **Localized Force:** The shear stress is concentrated around the bubble, allowing for highly targeted manipulation of fluids.

* **Tunable Intensity:** By adjusting the electrochemical parameters (voltage, current, electrode geometry), the intensity and duration of the shear stress can be finely tuned.

* **Non-Invasive Nature:** Unlike mechanical stirrers, this method is largely non-invasive, minimizing disruption to sensitive samples.

Applications in Microfluidics

The ability to generate controlled shear stress opens up a vast array of applications:

1. Enhanced Mixing

Achieving efficient mixing in microchannels is notoriously difficult due to laminar flow conditions. Electrochemically generated bubbles can induce chaotic advection, significantly accelerating the mixing process. Imagine needing to quickly combine reagents for a diagnostic test – this technology offers a solution.

2. Particle Manipulation and Sorting

The shear forces generated by bubbles can be used to move, trap, or sort microscopic particles. This is invaluable for applications such as:

* Cell sorting for diagnostics or research.

* Separating different types of nanoparticles for material synthesis.

* Concentrating rare cells from a larger sample volume.

3. Droplet Generation and Manipulation

In microfluidic systems that rely on droplets for reactions or analysis, precise control over droplet formation and movement is crucial. Bubbles can be used to pinch off droplets or guide their flow through complex channel networks.

### Advantages of Electrochemical Bubble Generation

* **Precision and Control:** Unparalleled ability to dictate bubble formation and thus shear stress.

* **Scalability:** The technology can be scaled to different microfluidic device sizes.

* **Integration:** Easily integrated into existing microfluidic designs with minimal modifications.

* **Low Power Consumption:** Electrochemical processes are generally energy-efficient.

### The Science Behind the Stress

The fundamental principle at play is the generation of a velocity gradient in the fluid due to the bubble’s expansion and movement. As the bubble grows, it pushes fluid radially outward. This outward motion, coupled with the fluid’s viscosity, creates shear stress on the surrounding fluid layers. The magnitude of this stress is directly related to the bubble’s size, growth rate, and the fluid’s properties.

For a deeper dive into the physics of fluid dynamics and shear stress, explore resources on fluid mechanics and boundary layer theory. Understanding these principles is key to fully appreciating the impact of this innovative technique.

### Future Prospects

The continued research and development in electrochemically generated bubbles promise even more sophisticated microfluidic applications. From advanced drug delivery systems to novel biosensors, the ability to precisely engineer fluid behavior at the microscale using bubble-induced shear stress is set to redefine what’s possible.

**Ready to explore the cutting edge of microfluidics?**

© 2025 thebossmind.com

Featured image provided by Pexels — photo by Tara Winstead